Optimize Your Life Sciences Workspace for Improved Outcomes, Enhanced Safety, and Increased Efficiency

- Jun 22, 2023

In the realm of life sciences, where precision and accuracy are paramount, creating an environment that fosters innovation, collaboration, and productivity is crucial. Acoustics and vibration control play a significant role in shaping the design and functionality of life sciences buildings. By understanding and implementing effective acoustic and vibration management strategies, acoustical consultants create spaces where researchers, scientists, and professionals can optimize their workspaces, leading to improved outcomes, enhanced safety, and increased efficiency. This article explores the importance of acoustics and vibration control in life sciences buildings and possible strategies that can be employed to create an environment conducive to scientific breakthroughs.

The Impact of Acoustics

Acoustic considerations are often overlooked, but they can profoundly influence the quality and efficiency of life sciences research activities. Unwanted noise can disrupt concentration, impair communication, and hinder accurate data collection. Research trials that involve patients also raise concerns about patient privacy, especially where practitioners have workspaces in close proximity to patient spaces. To mitigate these issues, acoustical consultants assess everything from external site noise and structural materials to space adjacencies, room finishes, and more.

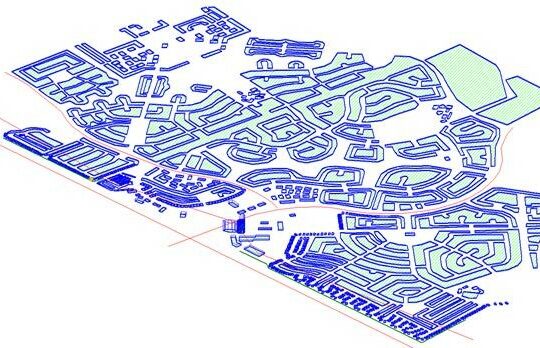

Life sciences facilities vary as much as the branches of life sciences themselves, meaning that each facility has unique functions and tolerances that require individual assessment and support to understand the best acoustical and vibration solutions. Acoustical consultants prioritize noise reduction through effective design and construction methods, making them an integral component of the design team from the earliest stages.

Key Acoustical Considerations Might Include:

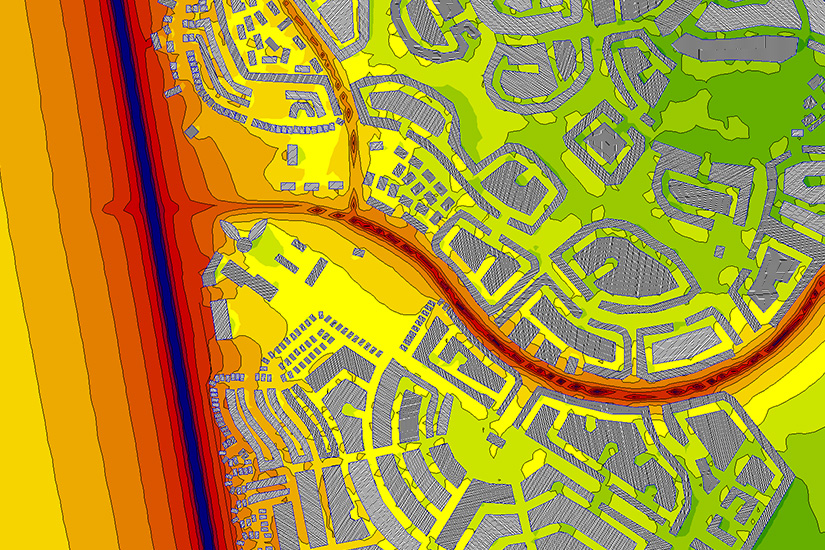

A Site Noise Survey: The best way to understand external noise factors is to conduct a site noise survey in the early stages of architectural planning and design. If the outdoor environment is noisy, attenuation through the exterior window-wall assembly can include the use of thicker glass panes, increased airspaces in insulating panes, or a reduced number and/or size of operable windows.

Sound Attenuation: While wall partitions and doors with excellent sound insulation properties are crucial for creating quiet spaces within the building, another solution to maintaining acoustical privacy is the use of recessed alcoves. These partially enclosed spaces provide a place where staff can collaborate but aren’t easily overheard because the pathway of sound between the person speaking and a potential listener is blocked. Employing materials with high sound absorption capabilities, such as acoustic panels, suspended baffles, or absorptive ceiling tiles, can also help decrease noise and increase privacy.

HVAC Systems: The heating, ventilation, and air conditioning (HVAC) systems in life sciences buildings should be designed to minimize ambient noise levels while ensuring efficient air circulation and meeting air exchange standards that are often required in these complex facilities. Locating rooms with sensitive equipment away from these loud mechanical systems is ideal, but when designers have limited layout options, mechanical equipment must be properly addressed. Specifying equipment with advanced technologies, such as low-noise fans, vibration isolation mounts, and duct silencers, can significantly reduce noise generated by HVAC systems.

Laboratory Equipment: Similar to HVAC systems, equipment in life sciences laboratories can produce substantial noise levels and exhaust fan vibration. With a thorough understanding of the building program and equipment to be utilized, machinery that produces abrupt noise may be located adjacent to unoccupied spaces or isolated from the surrounding environment using vibration isolation mounts or anti-vibration tables.

Managing Vibration in Life Sciences Buildings

Vibration control is essential in life sciences buildings to protect sensitive instruments, maintain stable working conditions, and prevent disturbances that could compromise research integrity. We know that mechanical systems and lab equipment can cause concern, but these aren’t the only sources of vibration. There can also be vibration transmitted to the building by nearby road traffic, trains, or machinery that can potentially affect delicate experiments.

Effective strategies for managing vibration might include:

Structural Design: In addition to maintaining specific levels of stiffness, incorporating vibration isolation measures into the building’s design, such as with isolation pads, floating floors, or resilient mountings, helps minimize vibrations caused by external factors. This is another instance where a site noise survey is helpful to determine if higher-performance structural systems are required to mitigate external or site vibration.

Equipment Placement: Proper positioning of heavy or vibration-prone equipment away from vibration-sensitive areas can prevent the transmission of vibrations. Isolating sensitive instruments from the floor or surrounding surfaces using vibration-absorbing materials or specialized mounts can provide additional protection. While isolation is an effective way to greatly reduce vibration transmission, it’s also critically important to ensure that a proper balance is maintained for rotating equipment. Just like an uneven load in your washing machine at home can produce uncomfortable noise and vibration, unbalanced fans and similar equipment can introduce excess noise and vibration into a building structure beyond the capabilities of isolation devices.

Active Vibration Control: In situations where vibrations are challenging to mitigate through passive measures alone, active vibration control systems, such as vibration-canceling devices or active dampers, can be employed to actively counteract and neutralize vibrations. Vibration canceling is achieved through a system that senses vibrations and produces equal and opposite vibrations, leaving almost no vibration at all.

Benefits of Effective Acoustics and Vibration Control

Enhanced Research Accuracy: By minimizing noise and vibrations, researchers can maintain optimal experimental conditions, reducing the risk of errors and ensuring accurate data collection and analysis.

Improved Concentration and Communication: A quiet and well-controlled environment fosters concentration and effective communication among researchers, promoting collaboration and idea sharing.

Safety and Compliance: Acoustic and vibration control measures contribute to the safety of both researchers and the building itself, ensuring compliance with regulatory standards and preventing potential hazards.

Well-being and Productivity: Providing a comfortable and disturbance-free work environment enhances the well-being and productivity of scientists, allowing them to focus on their work without unnecessary interruptions.

Acoustics and vibration control are integral components of designing and operating life sciences buildings. Addressing acoustical and vibration issues at the earliest point of design helps to alleviate costly change orders or potential post-construction work, ultimately setting the stage for scientific advancements. Through a comprehensive understanding of the building program, equipment that will be utilized, and building systems, acoustical designers can determine noise levels and vibration requirements throughout a facility and key areas of focus for sound mitigation. By prioritizing these factors, life science facilities become spaces where researchers are able to optimize their workspaces, leading to improved accuracy, increased productivity, and enhanced scientific breakthroughs.